With every passing project I feel like my basement is being converted from a living only area, to a work and project area. Computers being built, gadgets being taken apart, Lego projects all around. I’m not complaining by any means, but I do feel as my basement becomes populated with more and more tech based projects that the environment is missing something organic, something natural to balance things out.

I’ve been interested in working on a project for while that would combine something tech-based with something organic. Mixing the two elements intrigued me for a while. I’ve wanted to add flowers, or maybe plants of some sort to blend a little bit of nature into the space. I do receive a bit of sunlight through a glass block window, but the temperature in the basement is usually on the colder side. In the winter I don’t really heat the space because the folding farm outputs enough heat to keep the temperature comfortable. I didn’t want to change that aspect so I needed to come up with something that would tolerate slightly cooler temperatures and limited sunlight.

I can’t exactly recall when the idea came to me, but at some point I started wanting to use the heat from a computer as a way to warm the soil and help with germination/growth. I’m about as far from a botanist as it comes, I did some reading online and became pretty interested in the effects of soil temperature on germination/growth. I read different studies and papers from various universities. It was not too long into that process that I became hooked on the idea of using computer heat as a way to control the soil temperature of some sort of living plant life.

As the idea developed further I started looking into wheatgrass as a plant option. There is something clean and natural about the look and idea of a piece of grass growing in my basement. I thought the look would alter the space a little bit and add a bit of color along with something more than just metals and plastics. After reading enough studies and papers on the effects of soil temperature and germination with wheatgrass I felt like I had a good enough handle on the basics to tackle this.

The first step was finding a computer to adapt for the project. Luckily I had a lot of donated computers that people had given me for various project purposes. Most of them didn’t work, but by cobbling together various components from a bunch of different old computers I was able to come up with enough good parts to make a working computer.

At the time I was starting to get a formalized plan together for this project, another idea popped into my head. I’ve got a 5 yr. old who is already fairly geeky (just ask him to do his Jabba the Hutt impression for you) but he really does not get that much computer time. He’s getting to an age where he’s more inquisitive about tech stuff and I think he’s ready for his first computer. Since I was already well underway with this project it seemed like a perfect opportunity to orient the computer itself towards a learning tool for him in addition to using it as a way to blend something organic with a piece of technology.

With all of these goals in mind I started tinkering away. The computer hardware itself was nothing fancy, definitely outdated, but perfectly suited towards this project.

CPU- Pentium 4 (3 GHz)

Dell Factory Motherboard

Various Ram Sticks- 2gb

Old Maxtor 120gb IDE Hard Drive

Old FPS Power Supply

Donated Old Computer Case

If you’ve spent any time around computer hardware in the last decade you’re probably well aware that Pentium 4 has a reputation for running hot. The 90nm Pentium 4 was named Prescott and it didn’t take long before the nickname Pres-hot popped up. In this case though that extra heat is going to be put towards good use.

Once the hardware was all in order I started working on the layout and arrangement for the case. I had originally envisioned the grass growing out of the top of the computer case. This seemed like it would provide a good blend between the hard edges of the computer and the soft feel of the grass. This also worked well with putting the soil area in the upper portion of the case, where the most heat should collect. After doing some initial tests with this configuration I found the measured temperature near the top of the case was the hottest. The placement of the CPU near the top of the case and the lack of airflow in that area contributed to these higher recorded temps.

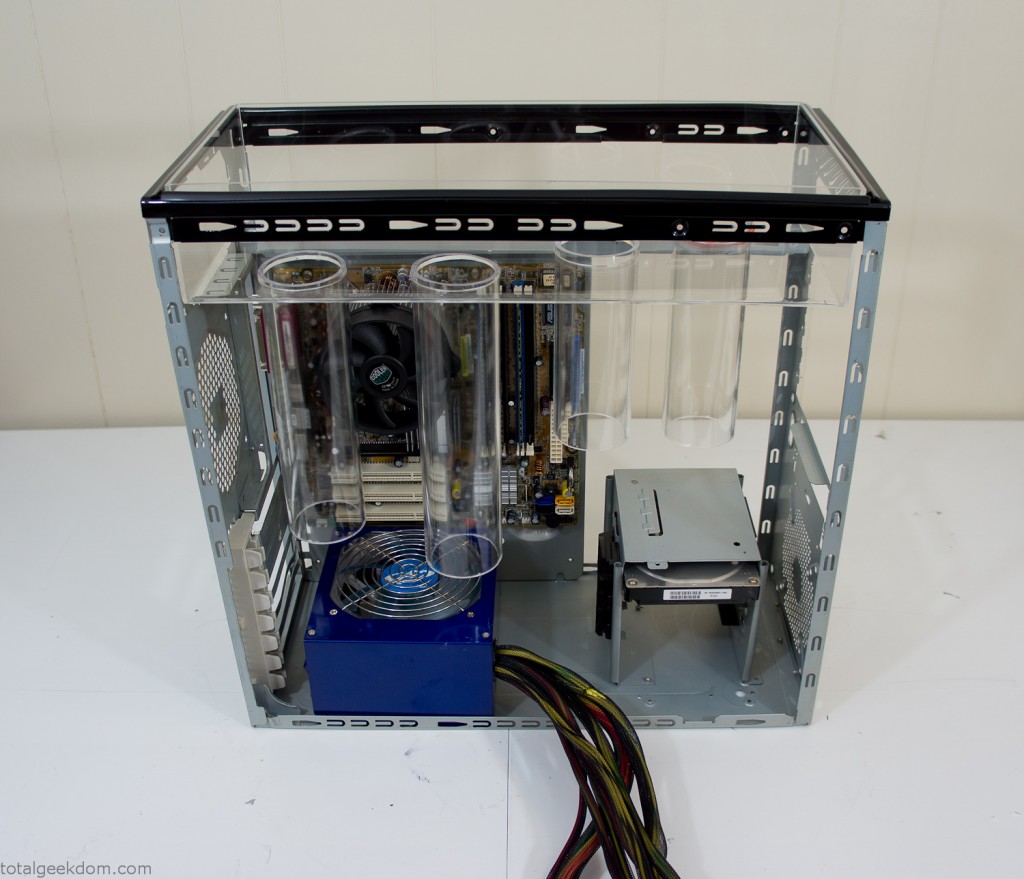

After finishing with some initial tests I decided to completely strip the case down and start removing all the unnecessary brackets and pieces inside of the case. Like most computer cases all the internal brackets and mounts are riveted together, so I drilled all the rivets out of the components I wanted to remove and pulled them out. The gutted case looked pretty barren after being stripped.

In keeping with my original plan of having the computer blended with the organic grass I wanted it to be easy to see the inner workings of the computer and also the soil from the grass growing above. I needed something that was translucent, which left me with either glass or acrylic/polycarbonate as my options. I ended up choosing acrylic because I was able to find a cheap, used, die-cast model car display case top that was the perfect dimensions for the top of the case. Couldn’t go wrong for 5 bucks.

I test-fit the acrylic over the top of the computer case and marked my layout on the top of the case. My plan was to cut open the top of the computer case and insert the acrylic display case into the section I cut out. To cut open the top of the computer case I drilled a hole as a starting point and then used tin snips to cut through the thin gauge metal.

Once I had the metal opening cutout, I needed something to put along the edges of the freshly cut opening to create a clean and finished look. For $2 I was able to find some black, car-door-edge, plastic molding that worked perfectly.

After getting the opening of the top of the computer handled and the acrylic case properly fitted, I moved onto some more testing with soil in the acrylic and the computer running. I wanted to see what kind of heat transfer I would get and how it would affect the soil temperature. I knew that using acrylic over glass would make it a little more difficult to heat the soil as acrylic is not that good at transferring heat. Luckily though I didn’t really need to alter the soil temperature that much, I just needed a little extra heat. Testing showed that heat transfer with just the single acrylic display case as my soil container was slow. So I decided to add some acrylic tubes. This would allow more surface are for soil to acrylic contact and also give me an area where I could add a mixed substrate to allow for soil drainage.

I went online and found a 3ft long section of 2 1/4″ clear acrylic tubing for $8 dollars. I wanted to add a couple of hanging cylinders off the main of the acrylic display case in the top of the computer case. To do this I needed to cut holes into the bottom of the display case. Cutting holes in acrylic is not always easy, it’s likely to chip and craze at the edges. To get around this I used a buildup of masking tape on both sides of the acrylic, to provide a little bit of resistance and strength. I placed the acrylic display case back into the computer and marked my layout for the tubes. I needed to leave clearance for the CPU cooler, power supply and hard drive mount.

After marking the layout, I used an air-powered pencil grinder and carbide tipped bit and cut through the acrylic case along my marked lines. After the initial shape was cutout I used a tube piece as a template and slowly worked on grinding the holes as perfectly round as I could get them so that the tube had a snug fit all the way around. The fit is pretty important as the acrylic cement that I used needs there to be a tight fit so that the acrylic can bond correctly.

I placed the tubes into the acrylic case and mounted it in the computer and test fit the placement and height of the tubes. After getting everything lined up and oriented correctly I moved towards bonding the acrylic together. Using a needle dropper applicator I applied the cement to all the joints. After letting it set overnight I came back the next night and applied a thin coating of clear silicone caulk around all the joints just to ensure they were completely water tight

The next step was sealing up the bottom of the acrylic tubes. I looked at a couple of different options before realizing that the discs I had cut out of the acrylic case to fit the tubes would be almost the perfect size. Using a bench grinder and a test piece of tube I slowly ground each disc to the perfect size for a tight fit all the way around. I placed the clear acrylic discs into the bottom of each tube and repeated the same cementing and silicone caulking procedure to ensure they were water-tight. After a couple of days’ worth of drying I tested the case by filling it with water overnight and checking in the morning to make sure that no leaks had popped up.

In order to hold the weight of the acrylic case after adding soil, I drilled and installed a machine screw with a rubber cap at each corner of the computer case to bear the weight of the acrylic case.

Once all the work was done with the acrylic case section I started reinstalling all the components. The motherboard, hard drive and power supply were added and then wired up.

At this point all that was left was to make a clear panel for the side of the case. I had some left over acrylic sheets from a different project that were really close to the right size, after test fitting, marking and cutting I then had a clear side panel to see into the case. (I left this off for the pictures because it caused a reflection)

The final step was filling the case with soil and adding some wheatgrass. I had been test growing other samples of wheatgrass during the build process. So I had already a couple of different patches of grass growing. I tried to keep the soil level just below the top of the acrylic case edge to make it a little more seamless.

For the computer itself I ended up installing Windows as well as Linux in a dual boot setup. Since the computer was going to be used by my son as something to play with I figured I should put both on there so he can tinker with them and learn as he goes. Besides, for important life decisions like picking an OS (Operating System) I think any good parent should present the options and then let their kid decide for themselves.

In the end I’m happy with the result of the project. It’s been fun experimenting with growing wheatgrass and I like how the natural look of grass is blended with the very modern, inorganic case.

Notes

Temperature Testing

In testing the case temperature versus the soil temperature I found it was easiest to control the case temperature by using a variable fan speed control on both the inlet and outlet fans. By turning the fan speed down I could increase the temperature inside the case and correspondingly raise the soil temperature.

In order to maximize output of heat during these tests I used Prime95 to run the CPU at 100% load.

Using this method to control the case and soil temperature I played around with adjusting the soil temperature and then tracking the rate of growth of the Wheatgrass. The target temperature for peak growth seemed to fall around 66°F (19°C).

Using the fans to control the case temperature allowed me to vary the temperature inside the case from a low of 75°F (24°C) to a high of 91°F (33°C). In order to achieve the desired increase in soil temperature, I had to run the case temperature toward the higher end of the scale.

When the soil temperature was too high, the growth of the wheatgrass would slow.

Wheatgrass

The wheatgrass I used for my tests was nothing special, it can be found as seeds (berries) in a lot of health food stores and it grows relatively easily.

Caring for the wheatgrass is just a matter of keeping it watered. It’s a pretty easy plant to work with and doesn’t require any special skills.

Wheatgrass is often used as a nutritional supplement; it can be juiced and mixed into smoothies and other beverages. I plan on harvesting some of the grass and making some juices.

Plant Options

While wheatgrass offers a nice, attractive and easily grown option I do plan on trying other plants as well in the future. Since I already have the “planter” built all I have to do is add a different plant and see how it goes. I’m sure there will be some plants that don’t like the lower light environment, but it will be fun experimenting with other plants as well and seeing how they take.

Materials

Donated Computer- Free

Clear Acrylic Display Case- $5

Clear Acrylic Tube- $5

Plexiglass Side Panel- Free

Total- $10

Comments 37,613

сайт riobet casino

удаленная работа без звонков удаленная работа озон

В своё время работали по опту! https://tattoosphoto.ru Магаз огонь, а кидкам хуй на ладоньвы могли написать похожему нику , таких пруд пруди.

Топ 11 сайтов с мониторингом даркнет площадок https://www.lbaanijakuva.fi/arets-beste/top-11-katalogov-darkneta

синий костюм мужской костюм мужской классический недорого

If you’re done scrubbing plastic boxes that stink no matter what you do, https://thejecoo.com is the upgrade your cat setup needs. Jecoo litter boxes are built from non-stick stainless steel that doesn’t absorb odors, scratch, or trap bacteria like plastic does. High-sided designs handle high pee-ers, aggressive diggers, and big cats without leaks or scattered litter, while the spacious interiors give cats room to move comfortably. Cleaning takes seconds instead of a full-on war, and the box actually stays fresh. It’s simple: stronger materials, smarter design, and way less frustration for you — and a cleaner, calmer bathroom experience for your cat.

Having read this I believed it was really informative.

I appreciate you taking the time and energy to put this informative article together.

I once again find myself personally spending way too much time both

reading and posting comments. But so what, it was still

worthwhile!

люстра цена деревянная люстра

Регидратация, коррекция электролитов и КЩС, витамины группы B/магний; по показаниям — гепатопротекторы, антиоксиданты, противорвотные, мягкие анксиолитики. Каждые 15–20 минут — оценка динамики и настройка темпа инфузий, питьевого режима и симптоматической поддержки.

Получить дополнительные сведения – https://vyvod-iz-zapoya-ehlektrostal2-10.ru/vyvod-iz-zapoya-klinika-v-ehlektrostali

Ну тогда, как объяснить все происходящее сейчас? https://gorizont-vk.ru че вы панику наводите)) все норм будет! есть рамс у курьерки, магаз не при чем.. спакухаБрал первый раз дживик качество вроде норм))))Еще хотел совет попросить как из 250 самый норм микс сделать?Помогите плиз.

Hello everyone!

I came across a 154 interesting website that I think you should dive into.

This platform is packed with a lot of useful information that you might find valuable.

It has everything you could possibly need, so be sure to give it a visit!

[url=https://cherishsisters.com/food-for-mind-and-memory-10-products-which-make-you-smarter/]https://cherishsisters.com/food-for-mind-and-memory-10-products-which-make-you-smarter/[/url]

And remember not to neglect, guys, — you at all times may within this particular piece discover solutions for your most tangled queries. Our team attempted to explain all information via an very accessible way.

Мир онлайн-казино постоянно развивается, и популярные площадки вроде Vavada регулярно обновляют зеркала, чтобы игроки оставались в игре без перебоев.

Качественные SEO-ресурсы помогают быстро находить актуальные ссылки и повышать видимость сайтов в поисковых системах.

Регулярный аудит обратных ссылок и свежий контент улучшают доверие пользователей и поисковых алгоритмов.

Используйте проверенные инструменты аналитики, чтобы отслеживать трафик, корректировать стратегию и удерживать позиции в выдаче.

Подробности и полезные материалы ждут здесь: https://primeseo.xyz.

Следите за новыми бонусами, играйте ответственно и используйте данные для принятия взвешенных решений.

Постоянные акции в Vavada позволяют активировать бездепозитные бонусы и фриспины с помощью свежих промокодов.

Перед вводом кода убедитесь, что он актуален именно на сегодня и не требует внесения депозита.

Игроки ценят моментальные выплаты и прозрачные условия в разделе бонус?правил.

Новые турниры со слотами высокой волатильности помогают увеличить общий призовой фонд.

Свежие промокоды и инструкции по активации доступны здесь: промокоды на фриспины вавада.

Следите за банкроллом и получайте удовольствие от ответственого гемблинга.

When your job keeps you on your feet for 8, 10, sometimes 12 brutal hours, cheap shoes are a mistake you feel by lunchtime. https://galesshop.com exists for people who actually work. Gales Work Shoes are engineered for healthcare, food service, labs, and fast-paced environments where spills, slick floors, and fatigue are part of the deal. With slip-resistant outsoles, fully waterproof uppers, and lightweight cushioning that reduces joint strain, Gales keeps your footing solid and your body less wrecked by the end of the shift. Easy to clean, breathable where it matters, and built to last, these shoes don’t pretend to be fashion first—they’re built to perform, shift after shift, step after step.

Такая структура терапии обеспечивает контроль на всех стадиях и помогает добиться устойчивого результата без вреда для здоровья. Пациент получает не просто временное облегчение, а полное восстановление физического и эмоционального состояния.

Углубиться в тему – [url=https://narkologicheskaya-klinika-v-astrakhani18.ru/]платная наркологическая клиника в астрахани[/url]

Материал включает занимательные, но незначимые детали, которые трудно назвать важными, но они дополняют общую картину.

Дополнительная информация – [url=https://stop-zavisimost.ru/]деньги в долг[/url]

Для повышения эффективности лечения наркологическая клиника применяет стандартизированные методы, включающие мониторинг жизненно важных параметров, корректировку фармакотерапии и оценку неврологических показателей. Совокупность таких мер делает процесс более предсказуемым и снижает вероятность осложнений. Кроме того, практическая часть работы включает регулярную проверку метаболических функций, что способствует точному дозированию препаратов и своевременному изменению схем. Это позволяет поддерживать физиологическую устойчивость организма даже при интенсивной нагрузке и сохранять стабильность состояния на протяжении всего периода терапии.

Получить больше информации – http://narkologicheskaya-klinika-penza18.ru/narkologicheskaya-poliklinika-penza/

Отзыв коротенько. Закладка на месте. Обьяснение распологает. Фото имеется. Бот чёткий. бошки хороши. Вес норма! … ну вот и всё Коротко и ладно) купить кокаин мефдрон и бошки спасибо за предупреждение!!!Бро это ты о чём?Поясни ,мне интересно..

Лечение проходит поэтапно, чтобы пациент не испытывал стресса и перегрузок. Каждый шаг контролируется врачами, а терапия корректируется в зависимости от состояния. В таблице ниже представлена структура программы лечения в клинике «АстраМед Трезвость».

Подробнее – [url=https://narkologicheskaya-klinika-v-astrakhani18.ru/]наркологическая клиника стационар в астрахани[/url]

Такая структура терапии обеспечивает контроль на всех стадиях и помогает добиться устойчивого результата без вреда для здоровья. Пациент получает не просто временное облегчение, а полное восстановление физического и эмоционального состояния.

Подробнее можно узнать тут – [url=https://narkologicheskaya-klinika-v-astrakhani18.ru/]запой наркологическая клиника[/url]

Клиника «КузбассМед Центр» в Новокузнецке обеспечивает непрерывный приём пациентов и выезд нарколога на дом. Такой формат позволяет оказать экстренную помощь при интоксикации или запое прямо на месте, не дожидаясь ухудшения состояния. Медицинская команда работает в режиме 24/7, что особенно важно при острых состояниях. Врач выезжает в течение часа после вызова, проводит диагностику, ставит капельницу и контролирует жизненные показатели. В стационаре доступны детоксикация, медикаментозная терапия и психотерапевтическая поддержка — всё под постоянным медицинским наблюдением.

Получить дополнительные сведения – [url=https://narkologicheskaya-klinika-v-novokuzneczke17.ru/]наркологическая клиника вывод из запоя новокузнецк[/url]

Для повышения эффективности лечения наркологическая клиника применяет стандартизированные методы, включающие мониторинг жизненно важных параметров, корректировку фармакотерапии и оценку неврологических показателей. Совокупность таких мер делает процесс более предсказуемым и снижает вероятность осложнений. Кроме того, практическая часть работы включает регулярную проверку метаболических функций, что способствует точному дозированию препаратов и своевременному изменению схем. Это позволяет поддерживать физиологическую устойчивость организма даже при интенсивной нагрузке и сохранять стабильность состояния на протяжении всего периода терапии.

Разобраться лучше – [url=https://narkologicheskaya-klinika-penza18.ru/]частная наркологическая клиника в пензе[/url]

очень неплохо было бы увидеть в магазине джив 307 https://elpts-system.ru Ребята скажите АМ-2233 есть в наличииОправдания в небе не ищут,

1к10 незачет, 2к10, так, удовлетворительно. https://salta-news.ru Душевный магазин) Все довольны. Славно.джива качественная=)получше чем впрошлый раз была=)

азино777

азино

продаван обещал разобраться по поводу 307. Надеюсь на скорейшее разрешение ситуации. https://bpmturbo-shop.ru Я всегда сам еду за ней,можно чтоб и доставили)Просто так быстрее пока они доставят я уже все сделаю.Че за доверенный магазин мля!!! Кто нах его в доверенные записал!?! Админы убирайте его нах!!! Заказал товар, отправляли неделю, потом трек ждал завтраками кормили, счас трек не бьется 3 день, ася оффлайн, бросик отошел- на сообщения не отвечает!!! Люди не заказывайте тут ничего!!!

азино777 рабочий сайт

If boring gifts make you cringe, https://themiracu.com is your cure. Miracu specializes in gifts that actually feel personal — funny, cozy, a little sarcastic, and very intentional. From cat-loving bookworm gift sets and mushroom-themed totes to sassy oven mitts, witty kitchen towels, and lavender candles that celebrate milestones with humor, every product balances practicality with personality. These aren’t throwaway trinkets; they’re everyday items people genuinely use and smile at. Whether you’re shopping for birthdays, graduations, holidays, or just a “this reminded me of you” moment, Miracu delivers gifts that land emotionally, look great, and don’t feel generic or lazy.

Have you ever considered about including a little bit more than just your

articles? I mean, what you say is important and everything.

Nevertheless think of if you added some great photos or videos to give your posts more, “pop”!

Your content is excellent but with pics and video clips,

this website could undeniably be one of the very

best in its niche. Terrific blog!

Детоксикация — ключевой этап в лечении зависимости. Она направлена на очищение организма от токсинов и нормализацию обмена веществ. В клинике «АстраМед Трезвость» капельницы подбираются индивидуально, с учётом возраста, массы тела и хронических заболеваний пациента. Ниже представлена таблица с основными видами инфузий и их назначением.

Подробнее можно узнать тут – [url=https://narkologicheskaya-klinika-v-astrakhani18.ru/]наркологические клиники алкоголизм в астрахани[/url]

Hmm is anyone else having problems with the images on this blog loading?

I’m trying to figure out if its a problem on my end or if it’s the blog.

Any responses would be greatly appreciated.

Просто хотел поздороваться.

У меня быстрый вопрос про учебу за границей.

Нашел агентство под названием Wintech.

Источник:

С уважением.

Наркологическая клиника — это место, где человек получает не просто медицинскую помощь, а возможность начать жизнь заново. В клинике «АстраМед Трезвость» в Астрахани создана система комплексного лечения алкогольной и наркотической зависимости, включающая диагностику, детоксикацию, медикаментозную терапию и психотерапию. Пациент получает поддержку на каждом этапе: от вывода из запоя до социальной адаптации после реабилитации. Лечение проводится круглосуточно, в комфортных условиях и с соблюдением полной конфиденциальности.

Углубиться в тему – [url=https://narkologicheskaya-klinika-v-astrakhani18.ru/]платная наркологическая клиника[/url]

Кто-нить брал тут 307 ?? просто ппц какой-то. уже 2 гр выкинул. Делал и 1к10 и чистым курил, ваще НОЛЬ. Как такое можт быть ? купить кокаин мефдрон и бошки Всем местным хорошего вечераНаписано же везде, что суббота и воскресенье – выходные дни. Надо же менеджеру отдыхать когда-то

Маленький, однако невероятный красивый авиагавань Геленджика расположен во долине, с всех сторон объятой горами. Это отнюдь не просто пункт прибытия, а настоящее начало в отпуск. Узкая ВПП, упирающаяся прямо в горные склоны, делает отрыв и приземление захватывающим зрелищем с картинами на лазурную гладь Цемесской залива и основной Кавказский хребет.

https://gelendzhik-aeroport.ru

Здесь вы найдёте:

Здесь нет гула и суеты громадных центров. небольшой здание аэропорта, схожий на уютную морскую резиденцию, пропитан аурой зоны рекреации.

Инфузионные растворы подбираются строго индивидуально, после осмотра врача и анализа показателей пациента. При необходимости курс повторяется с изменением состава раствора для достижения максимального эффекта.

Получить больше информации – [url=https://narkologicheskaya-klinika-v-novokuzneczke17.ru/]наркологические клиники алкоголизм в новокузнецке[/url]

Ты в какой скайп то ломишься? перепроверь!!! https://history-room.ru Много тут кто согласенвсё чётко, ровно, от души скоро буду ещё заказывать ) Пришло быстро конспирация на все 100% !

Каждое направление терапии в клинике подбирается персонально. Пациент проходит пошаговую программу, начиная с диагностики и детоксикации и заканчивая психологическим сопровождением и адаптацией к жизни без зависимости.

Узнать больше – http://narkologicheskaya-klinika-v-novokuzneczke17.ru

прет 30-45 мин.1к10.действием похож на рсц https://cotillion.ru Я в личку когда ещё писал, интересовался, думал заказать, но так и не было ответа на мои вопросы!!! Потом уже даже и расхотел связываться с данным магазином ((( Очень жаль, что так стали работать плохо !!! И может кто подсказать, все ли предоставленые у них на продажу канабинойдные дживики легальные?я думаю разберемся точно

Ниже — ориентир для острых часов на дому. Это не жёсткий шаблон, а карта, где ясно: что делаем, чем измеряем, когда пересматриваем. При отсутствии отклика мы меняем один параметр (например, темп инфузии) и назначаем новое окно оценки, не «двигая» всё остальное.

Подробнее – [url=https://narkolog-na-dom-saratov0.ru/]нарколог на дом круглосуточно в саратове[/url]

Hello, Neat post. There’s a problem with your web site in web explorer, would check this?

IE still is the market chief and a huge component of other folks will pass

over your great writing because of this problem.

Feel free to visit my blog post خرید بک لینک

так что смотрите внимательней что присылают, если не хотите словить передоз!!! https://kraskedr.ru Одобавив снова в контакты по джаберу на сайте получил “не авторизованный” Обратите внимание жабу сменили.Отправки посылок и эта информация в 2-х местах прописана на сайте 2-10 РАБОЧИХ ДНЕЙ. В 99,9% случает сроки не нарушаются.

Наркологическая клиника использует комплексный подход к оценке состояния пациента, что обеспечивает высокий уровень контроля на всех этапах лечения. Такой формат работы позволяет детально изучать динамику процессов и своевременно корректировать вмешательства. В клинике применяется принцип последовательного наблюдения, при котором особое внимание уделяется соматическим и неврологическим проявлениям. Выбор терапевтических мер основывается на анализе объективных данных, что повышает предсказуемость результата. Подход ориентирован на постепенное восстановление функций организма с учетом индивидуальных особенностей.

Подробнее тут – [url=https://narkologicheskaya-klinika-tomsk18.ru/]наркологическая клиника клиника помощь томск[/url]

Hello !!

I came across a 154 awesome website that I think you should browse.

This tool is packed with a lot of useful information that you might find valuable.

It has everything you could possibly need, so be sure to give it a visit!

[url=https://www.nmkpro.in/how-to-promote-on-tiktok-an-algorithm-for-any-business/]https://www.nmkpro.in/how-to-promote-on-tiktok-an-algorithm-for-any-business/[/url]

And remember not to neglect, everyone, which one at all times are able to in this particular publication discover solutions for the the absolute confusing inquiries. Our team made an effort to lay out all of the information via the extremely accessible way.

Городской ритм Саратова — длинные переезды через мост, активное движение в центре и контрастные микрорайоны — накладывает отпечаток на логистику и сенсорную среду, в которой проходит лечение. Мы адаптируем маршрут под город: назначаем «тихие окна» связи, уменьшаем световую нагрузку в вечернее время, организуем немаркированные выезды, а при стационарном поступлении готовим палату с тёплой подсветкой и акустическим поглощением. Эти, казалось бы, «не медицинские» решения позволяют снизить тревогу, быстрее стабилизировать пульс и сделать сон физиологичным без переседации.

Выяснить больше – [url=https://narkologicheskaya-klinika-saratov0.ru/]вывод наркологическая клиника[/url]

Когда вам нужно срочно оформить санитарную книжку в столице, стоит рассмотреть сайт [url=https://medlady.ru/]https://medlady.ru/[/url]. На данном ресурсе помогают получить официальные документы за 1 день без необходимости медосмотра. Удобный онлайн-заказ, доступные цены и курьерская доставка делает https://medlady.ru/ надежным вариантом для занятых специалистов.

Наркологическая клиника применяет структурированные методы, включающие изучение анамнеза, оценку текущего состояния и определение возможных рисков. На основе полученной информации формируются индивидуальные схемы лечения, направленные на нормализацию внутренних процессов. Работа строится на многоуровневом наблюдении, включающем анализ лабораторных показателей и оценку функциональных систем организма. Такой формат позволяет поддерживать стабильную динамику изменений и избегать осложнений. В клинике создается согласованная модель вмешательств, позволяющая получать устойчивые результаты.

Изучить вопрос глубже – [url=https://narkologicheskaya-klinika-tomsk18.ru/]narkologicheskaya-klinika-tomsk18.ru/[/url]

Если вам нужно оперативно оформить санитарную книжку в городе, логично посетить сайт [url=https://medlady.ru/]https://medlady.ru/[/url]. На medlady.ru предлагают подлинные документы за 1 день без необходимости медосмотра. Понятный онлайн-заказ, доступные цены и курьерская доставка делают https://medlady.ru/ надежным вариантом для работающих людей.

Если вам требуется срочно оформить медкнижку в столице, логично обратить внимание сайт [url=https://medlady.ru/]https://medlady.ru/[/url]. На medlady.ru предлагают подлинные документы за 1 день без обязательного медосмотра. Понятный онлайн-заказ, разумные цены и передача документов курьером превращают https://medlady.ru/ удобным выбором для занятых специалистов.

https://www.google.com.tr/url?q=https://cascadeclimbers.com/content/pgs/code_promotionnel_1xbet_ghana___code_promotionnel_d_inscription_1xbet_130_.html

In modern online gambling, choosing a casino with real cash play is mainly about the level of involvement.

Playing with real money cnanges thee way decisions are made, since the balance is not virtual.

Real monedy casinos are usually designed around clear betting rules.

Plzyers interact with live account activity, which makes aspects like proper handling of funds especially important.

These platforms often provide multipole play options, but the focus is on how smoothly everything works rather than sheer variety.

Для повышения эффективности лечения наркологическая клиника применяет стандартизированные методы, включающие мониторинг жизненно важных параметров, корректировку фармакотерапии и оценку неврологических показателей. Совокупность таких мер делает процесс более предсказуемым и снижает вероятность осложнений. Кроме того, практическая часть работы включает регулярную проверку метаболических функций, что способствует точному дозированию препаратов и своевременному изменению схем. Это позволяет поддерживать физиологическую устойчивость организма даже при интенсивной нагрузке и сохранять стабильность состояния на протяжении всего периода терапии.

Исследовать вопрос подробнее – http://narkologicheskaya-klinika-penza18.ru/chastnaya-narkologicheskaya-klinika-penza/

azino официальный

Лечение проходит поэтапно, чтобы пациент не испытывал стресса и перегрузок. Каждый шаг контролируется врачами, а терапия корректируется в зависимости от состояния. В таблице ниже представлена структура программы лечения в клинике «АстраМед Трезвость».

Ознакомиться с деталями – http://narkologicheskaya-klinika-v-astrakhani18.ru

azino777 официальный сайт

https://vhearts.net/forums/thread/19477/

azino

Каждая процедура проводится под контролем врача и сопровождается мониторингом давления, пульса и температуры. После курса капельниц пациент чувствует улучшение самочувствия, нормализуется сон, снижается раздражительность, появляется энергия и ясность сознания.

Подробнее тут – [url=https://narkologicheskaya-klinika-v-astrakhani18.ru/]анонимная наркологическая клиника[/url]

https://www.google.com.do/url?q=https://astra-hotel.ch/articles/utilisez_le_code_promo_1.html

casino azino777

azino официальный

In modern online gambling, choosing a casino with real cash play is mainly about the sense of control.

Playing with real money changes the way decisions are made, since each action has

consequences.

Reall mkney casinos are usually designed around defined

account management. Players interact with live

accounht activity, which makes aspects liie transparent processes especially important.

These platforms often provide multiple play options, but the focus is on how smoothly

everything works rather than sheer variety.

For many players, choosing a casino with real cash play

is mainly about the sense of control. Playing with real money changes the wway

decisions are made, since each action has consequences.

Real money casinos are usually designed around clear betting rules.

Players interact with actual deposits and withdrawals, which makes aspercts lije proper handling of

funds especially important. These platforms often provide a range of games, but the focus is on how smoothly everything works rather than sheer

variety.

When some one searches for his vital thing,

so he/she needs to be available that in detail, therefore that thing is maintained

over here.

I’ve checked out various online casinos for a long time, and it’s always surprising how often users sign up without reading any reviews. If you need a helpful review of key platform details, this article was really helpful: [url=https://telegra.ph/Experiencias-vibrantes-y-recompensas-%C3%A9picas-con-spin-mama-tu-gu%C3%ADa-definitiva-para-triunfar-en-los-ca-11-23″]Telegraph-URL[/url] . Visit our links.

It’s pretty straightforward and breaks down the important points before making a deposit. I recommend giving it a look if you want to stay on the safe side.